What is my Hip or Knee Replacement made of?

Advances in materials has let to a huge change in what implants are made of. The understanding of how articulation (joints/bearings) wear has changed the face of hip and knee replacement surgery, and their expected longevity. Interestingly, some materials used in hip replacements are not good for knee replacements and vice versa. Reporting from the Australian Joint Registry can give an understanding on some bearing surfaces, however it can only tell us which ones the bad ones are. We are going to focus on what the usual implant composition is with Dr Chien-Wen Liew, but also touch on a few of the alternative ones right down the bottom, for information only.

HIP REPLACEMENTS

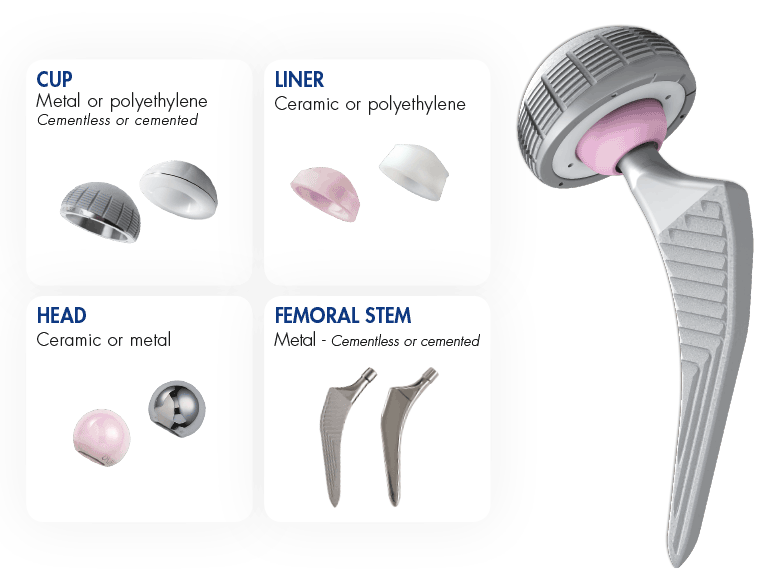

A hip replacement is composed of 4 main parts – the Stem and the socket – both which hold the articulating (or bearing) components. Each stem, ball, and socket need to be matched, as there are many combinations of size, shapes and designs, which are best for each and every patient. Utilising 3 dimensional pre-operative planning and patient specific technology, accurate measurements can be taken to ensure the correct fit, size, shape and permutations of the many different combinations are selected, to ensure the best chance of a “forgotten hip” at the end of recovery.

Utilised in almost all Direct Anterior Approach operations by Dr Chien-Wen Liew is the Amis Stem, which is composed of a metal stem, coated with hydroxyapatite. Hydroxyapatite is essentially artificial bone, with pores that have been designed to promote the quickest bone integration between the femoral bone and stem itself. This stem is what is considered a “cementless” design. This is preferred in our surgery due to the lack of complications associated with cementation, and the speed of integration of the stem with the bone. The core metal for the stem is titanium – aluminium – niobium alloy (Ti-6Al-7Nb). The composition of the stem was designed also to match the elasticity of the bone. If you can imagine a skyscraper swaying in the wind – this is similar to the stem design, which decreases the chance of mid thigh pain, which can occur from a very stiff stem in older designs.

The cup is composed of Titanium-Vanadium Alloy – the outer surface is a combination of both Ti Coating 100µm and HA coating.

The combination of the articulating parts is chosen to be Ceramic on Ceramic which studies show exhibit some of the lowest wear characteristics. Ceramics many years ago suffered from the potential of cracking, which is almost unheard of today with ceramics manufactured as a combination of Zirconium and Alumina. Most ceramics in the world for Total Hip Replacement surgery are created by a company called: CeramTec. We try to utilise Ceramic on Ceramic for all hip replacements – they are slightly more difficult to insert, but have the added bonus of a very long life.

What other articulations and materials are there?

The following are some of the articulations for hip replacements that are used – although utilised in the past, we generally do not utilise these unless specifically indicated.

Stainless steel

For cemented components, stainless steel is often used. It is very rigid, and polishes well. This is not used often as it is preferred to avoid using cement if possible. In cases of severe osteoporosis is when fixing particular fracture types, cement may be used.

Ceramicised metal

A more rarely used articulation is ceramicised metal which has been shown to have good longievity. It is not widely used as it is only recommended to be used with certain implants which are not within our desired scope of inventory. It is normally paired with a plastic liner, but showed improved wear characteristics over metal on plastic bearing surfaces.

Metal on Metal

Although in favour many years ago as part of Hip Resurfacing procedures, the use of metal on metal has been steadily dropping as hip resurfacings are phased out overall. Although very occasionally still used, hip resurfacing and metal on metal implants are no longer common place due to the requirement to monitor cobalt and chromium levels, due to the development of metal nano particles that can destroy local tissue and enter the blood stream. This has been seen in many types of metal on metal implants, and particular with 1 particular implant that was used over 10 years ago. It is not used in our offering, due to the risks posed by this articulation.

Metal on Plastic

The standard of implant articulation that is used currently is a metal ball, matched with a plastic liner. This is the most cost effective version of a hip articulation, and is the easiest to place within the hip, as the plastic is tolerant to less accurate insertion techniques than ceramic. Plastics have changed over the years, and are now extremely durable. It is a theory that newer plastics may not cause the same particulate damage to the bone as it wears, due to the decreased wear of newed plastics over older ones. For our practice, plastics are only used when a dual mobility implant is selected, which is where a small ceramic ball is connected to a large ceramic ball to decrease dislocation risk in complex revision scenarios generally.

KNEE REPLACEMENTS

LonGevity of knee replacements

Knee replacements have a very good long term revision rate – find out more by reading this article on implant longevity from data collected in Australia. The current combined rate of revision is only 9% at 19 years.

Total Knee replacements have generally had less material changes than Total Hip Replacements. In general, most are “Metal and plastic” with the majority made from the same metal. This is because it can be polished extremely smoothly, and because the knee has differing forces to a hip replacement.

The knee replacement femur and tibial components are made of Cobalt Chromium – which is known for its high level of biocompatibility as well as its strength.

The plastic is composed of Ultra High Molecular weight Polyethylene which over time, has undergone many changes to provide the lowest risks of cracking and breaking, combined with the longest wear characteristics.

What other materials are used

Cement

Cement is utilised in all Total Knee Replacements by Dr Chien-Wen Liew. The type of cement is usually one called Palacos, and has antibiotics within it. It has a 6 minute working time, and fully cures hard in 12 minutes. Cementation of the implant for knee replacements is different to that of hip replacements as the risks of cement embolisation is almost negligible in knee replacements as opposed to in hip replacements, where it is required to be pressurised into the femoral canal. Cement during knee replacement is mixed in a vacuum device and injected directly into prepared bone surfaces. Cement is Poly Methyl Methacrylate and is a light green in colour when used during surgery.

Patient specific technology

Although not implanted, patient specific technology utilises a specific plastic and resin created for each and every patient. This custom made device is used to be a rigid guide during surgery to ensure accuracy during bony preparation. The individualised moulds are removed prior to the final implants are inserted.

Other materials used

Not used in our inventory are other articulations in knee replacements. Again, ceramicised metal can be used, but is only available in limited designs. Trials of ceramics have largely been unsuccessful due to the differing nature of the forces going through the knee compared to the hip joint. Plastics have made different additives with many having been discarded over time. In general, the material composition of knee replacements has been relatively stable over the years when compared to the choices for hip replacement surgery.

WHAT TYPE OF SURGERY DOES DR CHIEN-WEN LIEW PERFORM

What methods will you receive with Dr Chien-Wen Liew

Dr Chien-Wen Liew has a dedicated practice in only total hip and total knee replacements. He no longer accepts new referrals for sports injury, trauma or other conditions of the hip and knee. This allows a dedicated focus to optimising all efforts towards a successful total hip replacemnt or total knee replacement.

total hip replacement

For over 8 years, all total hip replacements have been performed using the Direct Anterior Approach. This is an approach where no muscles or tendons are cut or detached during surgery. A cementless stem and socket combined with a ceramic on ceramic articulation will be used in most cases.

There are minimal restrictions, and early mobility. As part of the procedure, patient specific technology is utilised – meaning that a 3 dimensional scan is performed 2 months prior to surgery in order to create customised cutting jigs and accurate planning to ensure an accurate outcome and to decrease the amount of soft tissue damage during surgery. A specialised table is used during surgery to minimise touching any part of the leg except for the small operative field. During surgery an intra-operative scan is performed to double check that the procedure has matched with the Xrays, as well as the 3 dimensional plan as well as the individualised modelling. This ensures an accurate procedure in an effort to never return to the same hip again. There are no movement restrictions post operatively. Most procedures are performed under a spinal anaesthetic. No local anaesthetic is used during the procedure within the hip.

total knee replacement

The medial pivot design of the knee replacement has been a defining part of our practice. This allows the knee to glide in a natural movement. Combined with Kinematic Alignment, the procedure is now extremely planned using Patient Specific Technology. Kinematic alignment is where the final knee replacement is placed in a position to match a patient’s pre-arthritic anatomy rather than placed in what traditionally has been considered to be the “optimal” position for all patients. This means that each and every person will receive a position that mimics their own anatomy. Part of the benefit of this, is that there are no tendon, capsular, or ligamentous releases required, to balance the knee as we used to perform many years ago when each knee was aligned to be “straight”. This means that if you have been bow legged or knock kneed, pigeon toed or duck footed prior to developing knee osteoarthritis, then you will most likely be placed back into that position after surgery. This is done to regain the “forgotten knee” goal once recovery is completed. For every case, disposable instruments are used as part of the individualised patient equipment in order to decrease the risk of infection. We aim to walk our patients the same day, if surgery is performed in the morning, or first thing the following morning if performed in the afternoon. Most procedures are performed under a spinal anaesthetic. A nerve block is performed (adductor canal) in addition to a small amount of local anaesthetic at the back of the knee during surgery.